Need Help?

Precision Machining Consulting

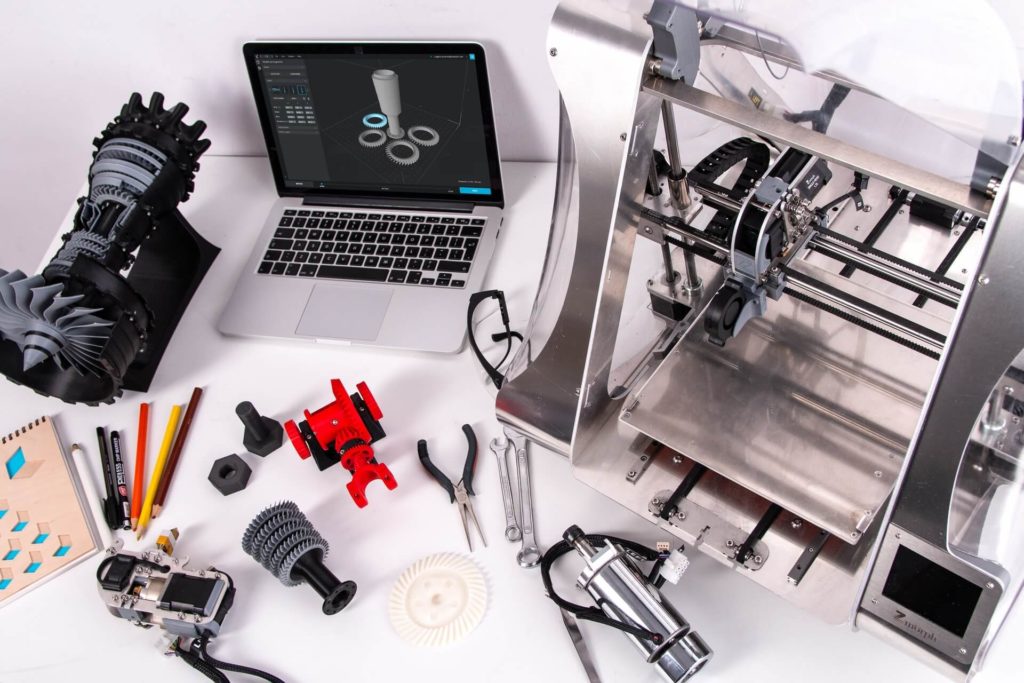

Precision machining is a form of industrial manufacturing that is useful in creating and designing several hardware-like tools, parts, and machines that play a crucial role in modern the manufacturing process to maintain process controls and tolerances that function under very tight specifications. Manufacturers use it in making up so many small and large parts that we utilize in our everyday life.

If an object has several small parts, you have to use precision machining to make it as this will make sure that they not only fit tightly but also function correctly. Thus, we can define precision machining as the use of the highest function of a program, engineering equipment, or talent, which pushes the limits of material science and design feature creation. The process takes place under stringent tolerances that are defined by any sub-set of the manufacturing parameters.

Precision machining has been evolving. The advancements in the related technologies push the limits that define precision machining and consistently improve its performance. The actual art in precision machining comes in with the marriage between human engineering design and computer-controlled design for the creation of highly controlled output, unique features. Advancements functionally drive it in durability, climate extremes, mechanical, chemical control, fluid dynamics, and the longevity that is a necessity in the modern-day hardware technologies.

Precision machining plays a crucial role in creating parts and tools in a stable and precise manner, and you can repeat it with the desired levels of durability, accuracy, and consistency.

As you can see, precision machining is not an easy process. As a result, most companies prefer to outsource this process to the right professionals. The challenge is determining which experts are the best for this type of work. At this point, Precision Machining Consulting comes in handy. These experts will help you through the process of bringing the right experts on board. The best brand for this purpose in the United States is NXT LVL ROI Business Consulting Services. We have a lot of hands-on experience in helping brands that are struggling with this function in the United States emerge victoriously.

The process of precision machining is subtractive because you will be removing materials from raw products to be able to create a finished product. You can use this technique to create a broad range of parts, items, and products for an unlimited number of different materials and objects. The components usually need tight tolerance variations from each part and from nominal differences meaning that there is minimal room for errors while producing the piece. The hallmarks of precision machining are well-controlled tolerances and repeatability.

When you use precision machining, you will be able to produce parts, components, and finished products that maintain a high degree of durability and extremely high degrees of tolerance. For instance, the parts that need to work together as part of the machine may require to align with a particular margin of 0.01 to 0.05mm. Precision machining and engineering will make sure that the parts the parts can be designed precisely and produced with high levels of accuracy all the time.

You can also use precision engineering when the components or tools require restoration or repair. After using the components or tools of a particular object for some time, they will need machine calibration, welding, or grooving to restore them to the original state. You can also achieve this objective through precision machining.

If you are looking for the best professional to help you through this process, you can trust us with the selection process. As you can see, it is not a process that you are going to leave to chances in any way. We have the right team of professionals who will screen various candidates on different grounds and help you to make an informed selection process.

The process of precision machining is a subtractive one in which process steps, engineered tools, and custom software are used with raw materials like composites, ceramic, metal, and plastic in creating the desired fine-featured products. In most cases, precision machining follows the instructions that come from the computer aided manufacturing (CAM) and computer aided design (CAD) programs.

The blueprints and programs increase the ability of meeting the tight tolerances. Most of the designs end up as computer aided and engineered designs but they start out as hand drawn sketches in the initial phases. We have the capacity to help you choose a professional who will work on the process of precision machining in the best way possible.

You can use precision machining with several raw materials such as glass, graphite, bronze, steel, composites, metal, ceramic, and plastic. To make an intricate removal of the raw materials and precise cuts, you will have to use a combination of tools. The tools vary depending on the raw materials that are being used. The frequently used tools are grinders, saws, electric discharging machine, and milling machine. The manufacturing equipment that is most commonly used is the computer controlled heavy machinery which is designed and utilized in removing substrate material to create finely detailed components and the piece parts. In some cases, even photochemical processes and high-speed robotics can be utilized to achieve the desired results for the final products. You can use precision machining to create both small and large parts and items as per the strict specifications, guidelines, and critical tolerances. There are so many ways in which precision machining can benefit your business.

If you are searching for the best precision machining experts to fulfil your large and small CNC machining run, it can be tricky to find the best company to work for you. The selection process can even be harder if you have not worked with precision engineering in the past. The best place to seek for assistance is NXT LVL ROI Business Consulting Services. We have business consultants who will guide you through the process of choosing the most fit precision machining company.

Everyone needs the peace of mind when handling any task that comes his way. It becomes even more important when dealing with important business matters. You need to begin your journey by identifying the most trusted precision manufacturing partners. As the name suggests, precision manufacturing is precise and hence calls for trustworthy professionals. You need a team with the right expertise and credentials to take you through the process.

Your top goal should be to choose the right partner during the initial attempt. We take several things into consideration to help you make the right choice. These include;

- Latest Techniques, Materials, and Technology

The human race continues to maintain and upgrade equipment and technology more often than we thought. We will help you to identify a partner who updates the outdated machines continually and upgrades regularly. The precision machining partner should be well versed in the CNC machines if you want to get the most precise results. The CNC machine is integrated in the industry and you should rate the professional using this machine that controls all of them.

Technology goes through a high level of revolution. We will help you to get a partner who keeps up with this ever-changing environment. Check into the technology that the machine partner uses and the technology that you need for the production.

Non-machining partners will encounter problems with the use of computers. CNC professionals have specific instructions to follow. They have to maintain efficiency and work effortlessly with the other team members in an environment that is time constricted.

A new partner will bring expansion and open doors right and left. On the other hand, the wrong partner will bring forth frustration and hinder the expansion of your company. Get a company that has the history of backing its customers when they need it the most. We will not disappoint you when you are going through the selection process.

Technology advances at an exponentially fast rate. Because of these advancements, the techniques and methods also evolve constantly. You will save a lot of time and money by choosing a partner who is up to date with the industry. Choose experts who know techniques that are more efficient or machines that can make more precise parts. Others experts use lighter materials but the final product has a higher strength than what you were thinking to use. Our consultants will help you to get a professional who will improve your finished product. We will check for people who are using the most innovative and latest machines in the market.

- Capabilities

The term capability refers to the nitty-gritty details of what the precision engineering company can deliver from the standpoint of machining. It is good to know the type of materials that the precision machining partner can work with, the techniques they implement, machinery they use, and the output and tolerances that they can achieve. It will allow the business owner to assess the timelines and whether you can do the machining in-house. You only need to outsource the whole process when it makes business sense. Our team will help you in making the right decision through precision machining consulting.

Therefore, it is crucial to look at the capabilities of the company. It does not matter whether you are interested in CNC turning services, CNC drilling services, or any other thing. You have to make sure that the company you are working with can product what you want to your specifications. It is better to choose a local company as you can pay a visit to the facility to get insights about its capabilities. We are here to make sure that you are getting the right company for your needs.

- Enthusiasm

Professionals who love their work are good at everything that they do. You may think that this criterion is unimportant. However, you must make sure that you choose a precision engineering company that is enthusiastic to pick up your work and job and also work with you. It will make the entire project to run smoother from implementation to planning, time management and even communication. Our business consultants will help you to get professionals who have a high level of enthusiasm for their work.

- Communication

The other factor that we pay close attention to when looking for precision machining experts for our customers is communication. The company should have engineers and experts on hand that you can talk to help you communicate your needs in a clear manner. If are able to speak directly with a decision maker or expert, you will be able to complete your project faster and with less possible errors. Therefore, the best precision machining company should approach your project with the spirit of getting it right during the initial attempt. It will help you to save a lot of effort, money, and time.

- Design Skills

The best precision machine experts understand and make adjustments to your design for a red line or model to print. Even though you may give the machining experts your own designs, this skill is an indication of depth of knowledge in the trade of machining. It can also help you to identify errors and support quick changes wherever necessary.

- Knowledge

The precision machining professionals have to bring a high level of expertise, experience, and knowledge to every project. We will make sure that this is possible through the thorough selection process. It is good to choose a company that has an in-depth understanding. Such a company will deliver more precision and care to make the exact pieces that you require to work with your assembly and meet the print accurately. We only recommend precision machining companies that talk to customers frequently and inquire about the print or design. Avoid experts who make assumptions as this will make them to machine unsatisfactory pieces.

As a business person, you want your products must produce meticulously precise results and you work with deadlines at all the time. Therefore, you should pay close attention to the collective experience and expertise of the team that you choose. You need CNC experts, machinists, and programmers to product the best products within the set timelines and budgetary constraints.

We will help you research potential partners and choose the best precision machining company. It is frustrating to choose a non-reliable partner who has no experience in the industry. Expertise is critical if your parts require fine-tuning hence a better bottom line. Choose a partner who knows the industry and its equipment.

- Kept Relations

Always shop for a precision partner who has connections with his customers. A bond goes beyond the screen to screen conversations. Make sure you get an accountable partner that you know by face and by name. In the psychological world, you know that business relations become better when you grow them as an actual form of friendship. Business is business even though it is more relieving for break out for some kind of life outside of work.

It is common to make a few mistakes in your personal life or any industry. However, when you have a partner who can learn from them and listen to you will move the production along. Employees can be highly scared to make a mistake and this may lead to a halt in the production until the issue is resolved. Employee relations are crucial if you want to move on well. The employees will work better if they have a good standing relationship with their employer. Go for a partner whose employees are happy as this will increase the level of productivity. As you look for the best precision machining experts, make sure you take a peek inside the facility. It is something that we are not able to overlook when helping you to identify the best partner through our consulting services. The small but impactful relationship goals matter a lot when evaluating the potential profession machining partner. We will help you to take care of this as you choose the best expert in the United States.

- Material Workforce

The various CNC machining companies use different materials in their work. Thus, you have to make sure that the one you choose has the ability to work in the materials that is required to make your finished components and parts. Some of the common materials include brass, copper, aluminum, steel, and so on. The workers should have the right knowledge to work on the materials that you use for your brand. Besides, the company should have the right tools and equipment to work on your material. What we do is looking on the experience that your company has in working with the said material. We want to make sure that you are bringing the right professionals. It is a crucial step and a small failure can see you lose the whole project.

- Technical Support

As long as you are dealing with a reputable precision machining company, you will rarely experience problems with the parts. However, in case of a challenge, the brand should be readily available to make necessary adjustments. It is good to get efficient and technical support whenever you have a problem. The way the company treats past customers is a reflection of how they will treat you. Therefore, we always analyze the comments from previous customers to know the level of support that you expect from the firm. We don’t want you to get into trouble with the company at any point especially when you need their support. Our consultants will look for as much information as possible about the company. The most important thing for us is helping you to get the most reliable precision machining expert in the region.

- Cost of Services

The last thing that we pay close attention to is the cost of the services. You need to strike a balance between the two elements of cost and quality. The guiding principle is to get superior products that come at a price that is highly competitive. One thing you need to remember is that the amount that you pay will ultimately determine the selling price of your products. Therefore, you need to consider the price in relation to the other issues that we have discussed. You don’t want to compromise on the quality at the expense of the price. Our professionals will help you to make the right assessment so that you can get the value for your money. It is always about getting the best from your investment. Our business consultants will look at various factors to help you choose the best bargain for the precision machining partner.

Our consultants will make sure that you are getting the best precision machining services in the region. We have so many brands in the United States that are experienced and licensed to handle precision machining services. When you get such a reliable company, you will be able to get high-quality and reliable precision machining services.

You have to make sure that you are using the several guidelines to select the best precision machining professionals. Reliability and availability are among the factors that you need to consider when making this choice. To make the right choice, you can rely on our precision machining services. We have helped so many brands in the region to make the right decision. You will never regret when you hire our business consultants.

NXT LVL ROI Business Consulting Services is the best brand in the United States. We have the capacity to help you make the right decision when hiring precision machining experts in the region. The price that we charge is relatively infinite in comparison to the benefits that you stand to get. We consider all the important factors when helping you to outsource these professionals. As a consulting firm, we have a long list of happy clients whom we have been serving. The guiding principle for all our services is value addition. Feel free to give us a call today if you want guidance in how to make informed business decisions.

At NXT LVL ROI Business Consulting Services, Our Expertise Resides Within These 3 Core Foundational Services:

Even though the above 3 core services is what our agency & consulting firm is about, we offer several other ancillary services below. Whatever your business or professional needs our, we’re your one stop shop consulting firm to discover & deploy proven solutions to you and your business.